Initiatives for Resource Conservation and Biodiversity

INDEX

- Approach and Goals for Water and Biodiversity Conservation

- Management of Water Resources

- Reduction of Waste and Resource Recycling

- Automatic inspection using Ishikawa Sanken image camera

- Introduction of Ishikawa Sanken Energy-Saving Air Conditioning Equipment

- Contribution to biodiversity

- Initiative of My Water Bottle Campaign

- Resource conservation Separate collection of cardboard boxes and valuable materials Yamagata Sanken

- Reuse and Recycling of Plastic Cases Yamagata Sanken

Approach and Goals for Water and Biodiversity Conservation

Fundamental Approach

The Sanken Group uses significant amounts of water and various chemical substances in the manufacturing of semiconductors. We recognize that our business operations and supply chain activities depend on the natural environment and have an impact on ecosystems.

Water resources are unevenly distributed across countries and regions, and natural environments vary by location. As we continue to learn about the relationship between our business and the local environment, we are committed to working collaboratively with all stakeholders to protect water and nature.

Through these ongoing efforts, we aim to achieve sustainable water use and contribute to the preservation and enhancement of biodiversity.

Goals

- Reduce unit-based consumption by 1% annually through 2030

- We formulate water usage strategies for business sites that are exposed to relatively high water risks or located in areas experiencing significant water stress.

- Properly manage chemical substances to minimize their environmental impact.

- Collaborate with stakeholders to implement biodiversity initiatives tailored to the characteristics of each region.

- Enhance employees’ awareness by deepening their understanding of the relationship between business activities, water, and ecosystems, and by encouraging participation in initiatives related to our core operations.

Key Risks and Opportunities

| Level of Risk | Target | Risk | Opportunities |

|---|---|---|---|

| Medium | Yamagata Sanken | Limitations due to the supply capacity of water pumps | Avoid operational shutdowns and reduce water utility costs through water reuse. |

| Yamagata Sanken | Concerns about operational shutdowns due to flooding of water supply facilities during heavy rainfall. | Prevent operational shutdowns through flood protection measures. | |

| Dairen Sanken |

There is a potential risk of future water supply restrictions due to the location of operational sites in areas with high water stress. | Avoid operational shutdowns and reduce water utility costs through water reuse. | |

| Low | Company-wide | Reputational risk arising from concerns about the impact of chemical substance use on biodiversity and human health. | Building trust through communication on chemical substance management |

Management of Water Resources

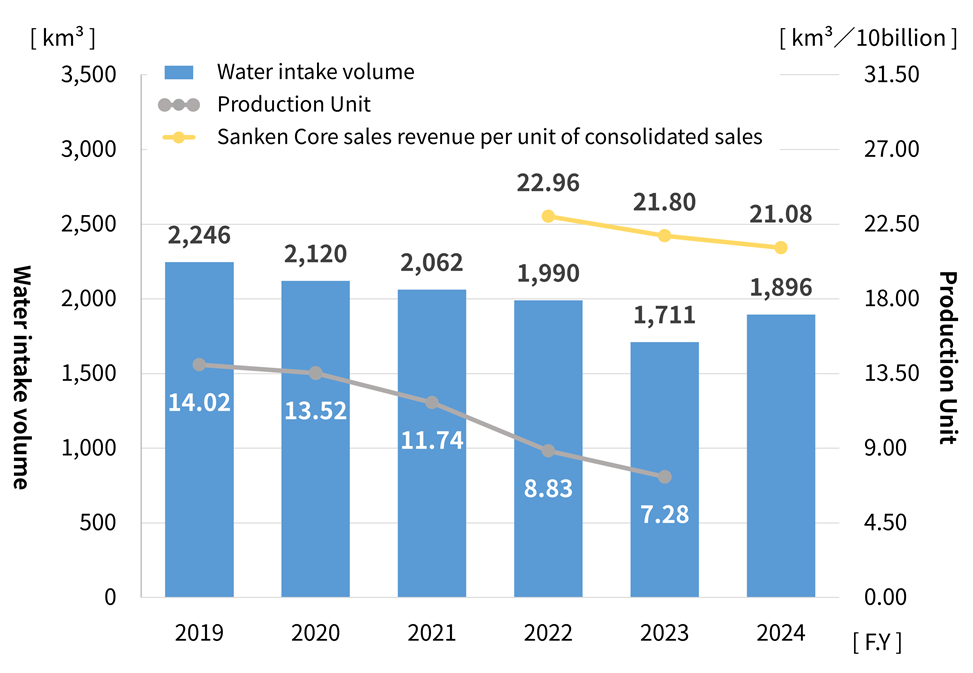

Trends in Water Intake and Sales Intensity

The Sanken Group utilizes water resources such as potable water, groundwater, and industrial water.

We recognize water resources as precious and limited resources, and from the perspective of biodiversity and ecosystem protection, we are striving to reduce water intake.

Regarding the "reduction of water intake," we have been promoting this on a factory-by-factory basis. However, going forward, we will set a goal to "improve intensity by 1% year-over-year" for the total in Japan and the Dalian Group, and work towards achieving this target.

Automatic inspection using Ishikawa Sanken image camera

We are working to improve production efficiency by changing visual inspections by people to automatic inspections using image cameras.

In 2015, we reduced the number of employees by approximately 30, including by actually adopting image camera inspections for internal visual inspections and by adopting image camera inspections with or without JCR in the JCR process.

Introduction of Ishikawa Sanken Energy-Saving Air Conditioning Equipment

With the use of CFC-free 22 (*) as a machine, we replaced the air-conditioning equipment in the refrigerator with new energy-saving equipment, which has resulted in more energy savings than the previous equipment.

Old system: 34,177 kWh/year

New system: 21,466 kWh/year 37% reduction

※Fluorocarbon-free 22: Complete elimination by 2020 of specified CFCs (HCFC) that are highly ozone-depleting

Contribution to biodiversity

Approximately six beech trees were discovered on the premises of Ishikawa Sanken Co., Ltd.'s Horimatsu Plant. It has been confirmed that these trees are a rare species of Japanese beech that grow in clusters at an altitude of just 33 meters—one of the lowest elevations known for this type of tree in Japan.

At Ishikawa Sanken, we believe that protecting these beech trees contributes to the conservation of the natural environment.

To ensure that this rare species is preserved for future generations, we have revised our site development plans and are committed to maintaining and protecting the area.

Initiative of My Water Bottle Campaign

Since August 2019, all of our domestic business sites have been implementing the "My Water Bottle Campaign Initiative" as the first initiative to reduce the amount of plastic waste generated in-house. In particular, we will curb the volume of waste in-house "PET bottles" and "disposable plastic cups," thereby contributing to the realization of a sustainable society that SDGs aims to achieve.

(Reference) Waste of PET bottles: 156,000 (approx. 4 tons)/year (Head Office, Tokyo Office, Osaka Branch, Nagoya Sales Office)

Resource conservation Separate collection of cardboard boxes and valuable materials Yamagata Sanken

As energy-saving and resource-saving activities, since September 2021 we have sorted and collected cardboard boxes that used to be solid waste fuel (RPF) and converted them into valuable resources.

Disseminated information to all employees and requested their cooperation.

The company-wide sorting is carried out to recycle waste.

The monthly average collection of 2,000 kilograms has produced a significant effect, and we will continue this effort as an effort to conserve resources.

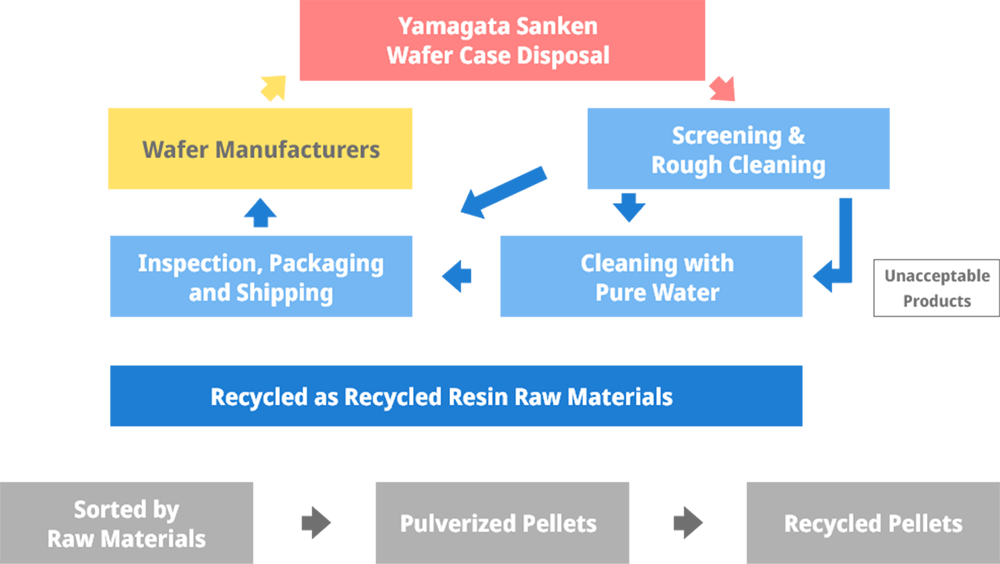

Reuse and Recycling of Plastic Cases Yamagata Sanken

We have been working on the recycling of wafer cases (plastic) since October 2021.

Until now, we have been carrying out the recycling process (recycling) as industrial waste, but we are currently implementing the reuse process (reuse) of wafer cases in cooperation with recycling companies and wafer manufacturers.